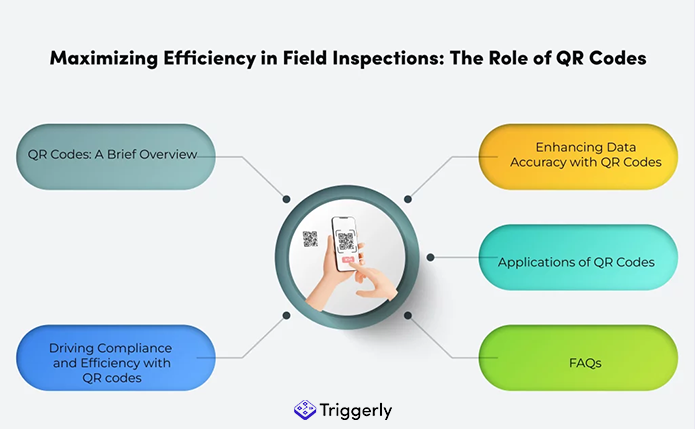

Maximizing Efficiency in Field Inspections: The Role of QR Codes in Data Accuracy and Compliance

1. QR Codes: A Brief Overview

In today’s fast-paced world, efficient field inspections are crucial for organizations across diverse industries. These inspections ensure the quality and compliance of processes, equipment, and locations.

However, traditional paper-based inspection methods can be time-consuming and prone to errors. To address these challenges, many organizations are now leveraging QR codes in their field inspection processes. In this article, we will explore the benefits of QR codes in field inspections and outline how they can be implemented effectively.

QR codes, or Quick Response codes, are two-dimensional barcodes that can be scanned using a smartphone or a dedicated QR code scanning device. QR codes can store a variety of information, such as text, URLs, and contact details. Their ability to store large amounts of data and their ease of use make them a powerful tool for enhancing field inspection efficiency.

Benefits of QR Codes in Field Inspections

The use of QR codes in field inspections offers several significant benefits.

Firstly, QR codes enable real-time data capture, allowing inspectors to record observations and findings on-site using mobile devices. This eliminates the need for manual data entry and reduces the chances of errors and data duplication.

Additionally, QR codes provide improved data accessibility and integrity. Inspectors can scan the code to access detailed information about equipment, locations, or inspection checkpoints, ensuring that they have all the necessary information at their fingertips.

Moreover, QR codes play a crucial role in ensuring regulatory compliance. By attaching QR codes to equipment, locations, or inspection checkpoints, inspectors can easily record their observations, noting any deviations from compliance standards. This helps organizations track and address compliance issues promptly, reducing the risk of penalties or reputational damage.

Implementing QR Codes in Inspection Processes

To leverage the benefits of QR codes in field inspections, organizations need to implement them effectively. This involves several steps.

Firstly, organizations need to create QR codes for each inspection checkpoint or item they want to track. This can be easily done using QR code generation tools available online or through specific software applications.

Once the QR codes are generated, they can be attached to equipment, locations, or inspection checkpoints. Inspectors can then scan these QR codes using their mobile devices to record their findings and observations. The data collected through the QR codes can be synchronized with a centralized database or inspection management system, ensuring that the information is readily available for analysis and reporting.

2. Enhancing Data Accuracy with QR Codes in Field Inspections

Accurate and reliable data is a cornerstone of effective field inspections. Inaccurate or incomplete data can lead to incorrect assessments, compromised safety, and regulatory non-compliance. QR codes play a vital role in enhancing data accuracy in field inspections. Let’s explore how QR codes achieve this.

Real-time Data Capture

QR codes enable inspectors to capture data in real-time, eliminating the need for manual data entry or transcription. By scanning a QR code, inspectors can access predefined data fields relevant to the inspection item or location. This ensures that the data captured is accurate and consistent, reducing the chances of human error.

Moreover, real-time data capture allows immediate action to be taken in response to inspection findings. If an issue is identified, such as a safety hazard or non-compliance, inspectors can initiate corrective actions directly from their mobile devices, ensuring a timely resolution and minimizing potential risks.

Improved Data Accessibility and Integrity

QR codes provide inspectors with easy access to relevant information during field inspections. By scanning a QR code, inspectors can instantly retrieve comprehensive details about the equipment or location being inspected. This includes product specifications, maintenance history, safety procedures, and any previous inspection findings.

Furthermore, QR codes ensure data integrity by reducing the risk of manual data entry errors. When inspectors scan a QR code, they directly capture the encoded information, eliminating the need for manual input. This improves the accuracy and reliability of the data gathered during inspections, enhancing the overall integrity of the inspection process.

Ensuring Regulatory Compliance through Accurate Data

For organizations in various sectors, following industry regulations and standards is essential. QR codes help enforce regulatory compliance by facilitating accurate data collection and documentation during field inspections. Inspectors can use QR codes to record compliance-related observations, attach images or videos as evidence, and document any corrective actions taken.

By ensuring that accurate and up-to-date compliance data is readily available, QR codes enable organizations to respond promptly to regulatory inquiries or audits. This reduces compliance-related risks, enhances organizational transparency, and helps maintain a positive reputation within the industry.

3. Driving Compliance and Efficiency in Field Inspections

Efficiency and compliance are two key objectives of field inspections. QR codes play a pivotal role in driving both compliance and efficiency in field inspections. Let’s explore how QR codes achieve these outcomes.

Automation of Inspection Processes

By incorporating QR codes into the inspection process, organizations can automate various tasks that were previously done manually.

For example, when a new item is created, a QR code can be automatically generated and associated with the item. This eliminates the need for inspectors to manually label or track the item, saving time and reducing the chances of errors.

Furthermore, QR codes can be used to trigger automated actions within the inspection workflow.

For instance, scanning a QR code can initiate the next stage of the inspection process or assign specific tasks to team members. This automation streamlines the inspection workflow, improves task allocation, and reduces the administrative burden on inspectors.

Streamlining Compliance Tracking

Tracking and managing compliance-related data is a complex task. QR codes simplify this process by providing a standardized way to record and track compliance information. Inspectors can scan QR codes associated with compliance requirements, instantly accessing relevant procedures, standards, or instructions.

Additionally, when QR codes are scanned, any updates or changes made in real-time are automatically synchronized with the centralized inspection management system. This ensures that compliance documentation is current and accessible to all stakeholders, including inspectors, managers, and auditors.

Enhancing Field Inspection Productivity

QR codes significantly enhance field inspection productivity. Inspectors can perform inspections more efficiently by scanning QR codes to retrieve essential information, record observations, and complete inspection forms on their mobile devices. This eliminates the need to carry bulky reference materials or manually transcribe data.

Moreover, QR codes enable field inspection teams to work in a synchronized manner. When inspectors scan QR codes, the data captured is instantly available to the entire team, ensuring uniformity and consistency in the inspection findings. This collaborative approach enhances productivity, reduces rework, and accelerates the inspection process.

4. Applications of QR Codes in Field Inspections

QR codes have diverse applications in field inspections across various industries. Let’s explore some practical examples of how QR codes can be utilized effectively.

Inventory Management

QR codes can revolutionize inventory management by enhancing stock tracking and monitoring. Each item in the inventory can have a unique QR code, allowing warehouse staff or store employees to scan the code and access detailed information about the item. This includes stock levels, expiration dates, or product specifications. Scanning QR codes also enables users to update inventory records, trigger replenishment orders, and streamline stocktaking processes.

Asset Tracking

Companies with a large number of assets, such as equipment, vehicles, or tools, can benefit from using QR codes for asset tracking. QR codes can be attached to each asset, enabling maintenance personnel or field workers to access asset history, maintenance schedules, and update asset status directly from their mobile devices. This ensures accurate and up-to-date asset information, reduces the risk of lost or misplaced assets, and improves maintenance efficiency.

Facility Management

In large facilities or campuses, QR codes can be strategically placed at various locations, such as rooms, equipment, or maintenance areas. Facility managers or maintenance personnel can scan QR codes to access maintenance schedules, equipment manuals, or report maintenance issues directly from their mobile devices. This streamlines facility management processes, enhances data accuracy, and enables efficient maintenance planning.

5. FAQs

How do QR codes enhance real-time data accuracy in field inspections?

QR codes enhance real-time data accuracy in field inspections by enabling inspectors to capture data directly from the source using mobile devices. By scanning QR codes, inspectors can access predefined data fields, reducing the chances of human error or data duplication. This ensures that the data collected is accurate, consistent, and immediately available for analysis.

What role do QR codes play in improving compliance during field inspections?

QR codes play a crucial role in improving compliance during field inspections by providing a standardized way to record compliance-related observations, attach evidence, and document corrective actions. By scanning QR codes associated with compliance requirements, inspectors can ensure that relevant procedures or standards are followed, facilitating regulatory compliance.

Are there any specific benefits of using QR codes for revolutionizing field inspections?

Yes, using QR codes for field inspections offers several specific benefits. These include real-time data capture, improved data accessibility and integrity, automation of inspection processes, streamlined compliance tracking, enhanced productivity, and reduced administrative burden. QR codes enable organizations to optimize their field inspection workflows, improve data accuracy, and ensure compliance with industry regulations.

Conclusion:

In conclusion, QR codes are invaluable tools for maximizing efficiency in field inspections. They facilitate real-time data capture, improve data accuracy and accessibility, ensure regulatory compliance, and streamline inspection processes. By leveraging the power of QR codes, organizations can enhance their field inspection workflows, optimize data accuracy, and drive compliance in a professional and efficient manner.

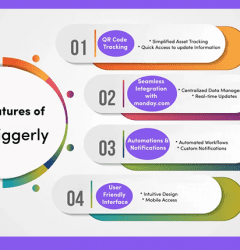

For those seeking advanced QR solutions, tools like Triggerly on monday.com can further enhance your field inspection by providing cutting-edge features and integrations that streamline operations and improve accuracy.

Recent Posts

- How to use Smart Columns to identify key dates like holidays and label them automatically for better resource allocation on monday.com boards

- How to use Smart Columns to never miss an SLA target again on your monday board

- How to use Smart Columns for Casting advanced formulas into standard columns

- How to use Smart Columns to set regional numbers & dates formatting on your monday.com boards

- How to use Smart Columns to enforce conditional logic to monday.com board status columns

- How to use Smart Columns to validate any phone number stored in your monday.com phone board column

- How to use Smart Columns to enforce Mandatory Columns to any standard column on monday.com board