The Role of QR Codes in Optimizing Inventory Management:

In the fast-paced world of modern business, effective inventory management is crucial for maintaining competitiveness and meeting customer demands. Traditional inventory tracking methods often involve manual data entry, which can be time-consuming and error-prone. However, with the advent of technology, businesses are increasingly turning to QR codes to streamline their inventory management processes.

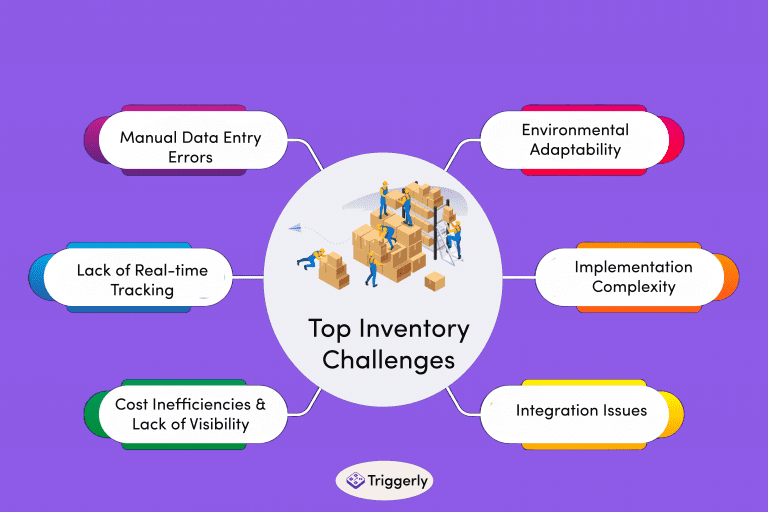

Challenges in Inventory Management

1. Manual Data Entry Errors

Traditional inventory management often involves manual data entry, which is prone to errors such as typos or misinterpretations.

2. Lack of Real-time Tracking

Without real-time tracking, businesses may struggle to have up-to-date information on stock levels, locations, and movements.

3. Cost Inefficiencies

Traditional inventory management methods can be costly and time-consuming, especially when errors lead to stockouts or overstocking.

4. Lack of Visibility

Without detailed information about inventory items, businesses may struggle with visibility into product specifications, expiration dates, or batch numbers.

5. Integration Issues

Integrating inventory management systems with other business systems, such as accounting or ERP systems, can be complex and time-consuming.

6. Implementation Complexity

Implementing new inventory management systems can be challenging, requiring extensive training and resources.

7. Environmental Adaptability

Different inventory environments may require different tracking solutions, leading to complexity and inefficiency.

These challenges highlight the importance of effective inventory management systems and practices. Addressing these issues can lead to improved operational efficiency, cost savings, and enhanced customer satisfaction.

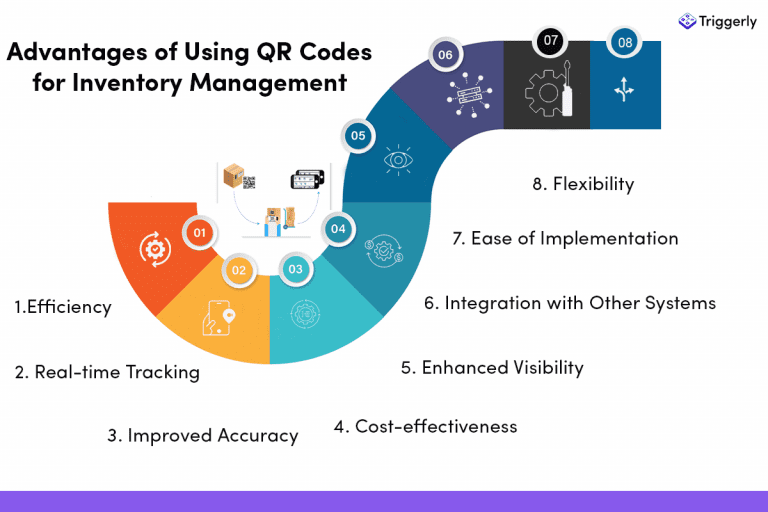

Advantages of Using QR Codes for Inventory Management and How They Address These Challenges

1. Efficiency

QR codes enable quick and accurate data capture, eliminating the need for manual entry and reducing the risk of errors. Employees can simply scan QR codes with mobile devices, saving time and improving efficiency.

2. Real-time Tracking

QR codes facilitate real-time tracking of inventory movements, providing businesses with up-to-date information on stock levels, locations, and movements. This helps prevent stock outs, overstocking, and enables better decision-making.

3. Improved Accuracy

By minimizing manual data entry, QR codes help reduce errors such as typos or misinterpretations, enhancing the overall accuracy of inventory records.

4. Cost-effectiveness

Implementing QR code-based inventory management systems is often more cost-effective than traditional methods. The low cost of printing QR codes and the savings from improved efficiency make it a worthwhile investment for businesses.

5. Enhanced Visibility

QR codes can store additional information about inventory items, such as product specifications, expiration dates, or batch numbers. This improves visibility into the inventory and aids in quality control and compliance efforts.

6. Integration with Other Systems

QR code-based inventory management systems can easily integrate with other business systems, such as accounting software or enterprise resource planning (ERP) systems. This streamlines processes and enables seamless data flow across different departments.

7. Ease of Implementation

Implementing QR code-based inventory management systems is straightforward. Once QR codes are generated and attached to inventory items, employees can immediately start using them for inventory tracking without extensive training.

8. Flexibility

QR codes can be used in various environments, including warehouses, retail stores, or manufacturing facilities. They can be printed on labels, stickers, or directly on products, making them adaptable to different inventory management needs.

Conclusion:

QR codes offer a practical and efficient solution for managing inventory in today’s business environment. By leveraging QR codes, businesses can improve efficiency, accuracy, and visibility in their inventory management processes, ultimately leading to better decision-making and enhanced competitiveness. Platforms like monday.com offer innovative QR tracking solutions that integrate seamlessly with popular project management tools, further enhancing overall efficiency. If you want to know more about this platform, click this.

.

Related Post

Recent Posts

- How to use Smart Columns to identify key dates like holidays and label them automatically for better resource allocation on monday.com boards

- How to use Smart Columns to never miss an SLA target again on your monday board

- How to use Smart Columns for Casting advanced formulas into standard columns

- How to use Smart Columns to set regional numbers & dates formatting on your monday.com boards

- How to use Smart Columns to enforce conditional logic to monday.com board status columns

- How to use Smart Columns to validate any phone number stored in your monday.com phone board column

- How to use Smart Columns to enforce Mandatory Columns to any standard column on monday.com board